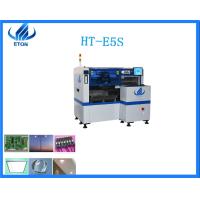

Introduction

1. Machine is intelligent. SMT Machine is very easy for operate.

Equipped with good human interface

Workflow of SMT placement machine: board feeding and mark

recognition-> automatic learning-> nozzle selection->

feeder selection-> component picking-> component inspection

to evaluate-> placement-> nozzle return- > Out board

2. Machine is high speed. ETON high speed mounter machine one hour

capacity could reach 4000 Meters

3. Machine is save labor. One smt line only take 1-3 labors.

Technical Paremeter

| PCB Size | 500*450mm |

| heads | 10PCS |

| Feeder station | 52PCS |

| Components | 0201~15MM packaging material and IC material(Optional fixed camera

for 0201~35*35MM), Other component size can be customized |

| X,Y,Z Axis Drive way | High-end magnetic linear motor |

| Mounting Speed | 48000 CPH(Under best condition) |

✅ High-precision patch: using advanced visual recognition system,

the placement accuracy can reach ±0.01mm

✅ High-speed operation: efficient motion control system, improve

production speed, support mass production

✅ Strong compatibility: support 0201, 0402, 0603 and other

different specifications of components, suitable for all kinds of

PCB production

✅ Intelligent control: humanized operation interface, support

offline programming, simple and easy to learn

✅ Stable and durable: high-quality components + high-strength

structural design to ensure long-term stable operation of the

equipment

Full automatic SMT line Solution

In SMT Line, there are automatic stencil printer machine, pick and

place machine, reflow oven machine, loader and un-loader machine.

Different SMT line design will be little different. Some factory

will using one automatic stencil printer machine for different SMT

line. ETON will provide the professional suggestion for the line

design.

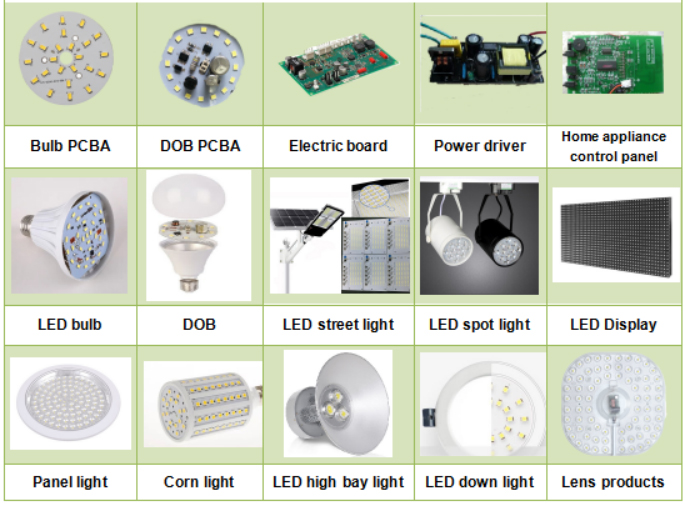

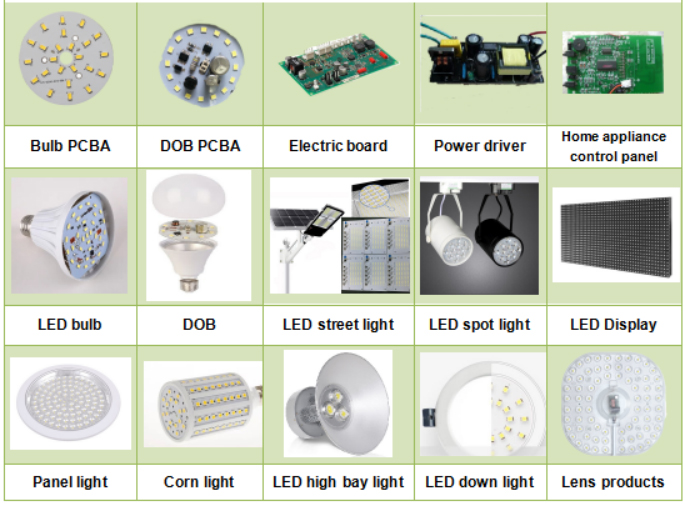

Application

Pre-sale

1)Provide equipment, such as pick and place machine, stencil

printer, reflow oven, conveyor,etc

2)SMT whole line solution, based on customer’s factory layout,

requirement, product, etc.

On-sale

1)Real-time follow-up of the production situation of the customer’s

machine.

2)Inform the customer of the production progress with video or

photos.

After-sale

1)On-site Free installation.

2)One-year Warranty factory service.

3)Two regular visits customer one year.

4)Free technical training

Technical support

1)Free technical training of operating and maintenance.

2)7*24 hours technical online support.

3)Local engineer in India(Delhi, Mumbai and Daman), Turkey, Egypt.

FAQ

Q: How is the Pick And Place Machine packaged?

A: The Pick And Place Machine is packaged in a wooden case.

Q: How long does it take to deliver the Pick And Place Machine?

A: It takes 30 days to deliver the Pick And Place Machine.

Q: What payment terms are available for the Pick And Place Machine?

A: The payment terms for the Pick And Place Machine are T/T, LC.

Q: How many Pick And Place Machines can be supplied per month?

A: A maximum of 50 Pick And Place Machines can be supplied per month.

Contact David

Whatsapp/Wechat: +86 13827425982