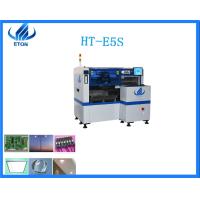

LED autimatic assembly machine led bulb production line / assembly

machine

The machine is introduced

1. This is multifunctional machine with double module,total 20

head,each part 10 head, can produce two

types of products at the same time.

2. The X axis is magnetic liner motor,Y axis and Z axis is servo

motor,very good performance and high accuracy.

3. It's intelligent,can produce different types of LED light and

electric board,such as bulb ,strip, Panel, Downlight,

streetlight,power driver, other electronic boards, etc

4. Its high precision(accuracy),apply to LED

chips,resistor,capacitor,IC,shaped components etc.

5. It is highspeed machine,the optimum speed is 80000CPH

Dimension (L*W*H) | 1200*1930*1500mm |

Total weight | 2500kg |

PCB Length width | Max:450*330mm Min:80*80mm |

PCB thickness | 0.1-6mm(If<0.6mm need jig) |

PCB clamping | pneumatic |

No.of feeders station | 64 PCS |

No.of head | 20 PCS |

Mounting speed | 80000 CPH |

Power | AC 380 V |

Operating environment | 6 KW |

What is smt device

The so-called SMT is both surface assembly technology (surface

mount technology) (abbreviation of Surface Mounted Technology), and

is currently the most popular technology and process in the

electronic assembly industry. The SMT equipment refers to the

machines and equipment used in the SMT processing process. The most

basic equipment includes: fully automatic printing machine,

placement machine, and multi-temperature reflow soldering.

We provide smt production line

ETON manufacturer can provide whole smt line machine for different

products, like the tube, bulb, flexible strip, DOB, display, lens,

panel light, downlight,electric board,etc.

SMT equipment operator job responsibilities

1. According to the squad leader's transfer plan, make

pre-production preparations in advance, such as materials, solder

paste, steel mesh, etc .;

2. According to the squad leader's arrangement, do a good job of

PCB printing and post-printing inspection;

3. Strictly implement the solder paste / red glue storage and use

control process;

4. Strictly implement steel mesh cleaning specifications;

5. In the production process, it is responsible for loading,

refilling, and matching of the machine, filling in the refilling

record form and sealing the sample, and notifying IPQC to confirm

the loading and refilling;

6. Confirmation of the first piece of production, whether there are

missing stickers, reverse, etc., fill in the first piece and send

the inspection form to notify IPQC to confirm the first piece

again;

7. After the first item is confirmed by IPQC, it must be confirmed

whether the furnace temperature is the product temperature before

passing the furnace, and whether the furnace temperature is normal;

8. After the production of the model is completed, remove all the

materials on the equipment, return the materials to the material

storage area of the SMT workshop according to the bill of

materials, and fill in the replenishment list (material code,

material model, quantity, etc.) required for the missing product

And return the process documents, BOM and other production

materials used in the production process to the monitor;

9. After the shift, do the daily maintenance of the equipment,

clean and sanitary, bulk materials search, and make related

reports;

10. Complete other tasks arranged by the leader.

Main process of SMT Line for DOB manufacturing

Step one: Print Solder paste on PCB

Step two: Mounting LED chip and capacitor big components on PCB.

Step three: Heating solder paste with PCB to welding together the component with PCB.

Different type of DOB PCBA

The PCBA of Linear bulbs

RT-1 SMT line not only suitable for DOB and bulb, but also suitable for many other products, such as: