Automatic stencil printer Two independent motorised print heads

The Function of Solder Paste

Solder paste is a new type of welding material accompanied by SMT.

It is a paste mixture formed by mixing solder powder, flux and

other surfactants and thixotropic agents. Mainly used in SMT

industry PCB surface resistance, capacitance, IC and other

electronic components welding.

In the 1970s, Surface Mount Technology refers to printing and

coating solder paste on the solder paste pad of printed circuit

board, and accurately sticking the surface mount components on the

solder paste pad, heating the circuit board according to a specific

reflux temperature curve, so that the solder paste can melt. The

alloy component is cooled and solidified to form solder joints

between components and printed circuit boards to realize

metallurgical connection technology.

Solder paste is a new kind of welding material accompanied by SMT.

Solder paste is a complex system, is made of solder powder, flux

and other additives mixed paste. The solder paste has a certain

viscosity at room temperature, which can initially stick the

electronic components in the established position. At the welding

temperature, with the volatilization of solvent and some additives,

the welded components and printed circuit pad will be welded

together to form a permanent connection.

Working mode

Using scraper, stencil, PCB is fixed by vacuum suction. The optical

positioning points (MARK points) of the substrate and the stencil

on the worktable are aligned by the camera of the printer, and then

the substrate and the stencil are finely adjusted so that the

pattern of the substrate pad and the opening pattern of the stencil

are completely coincident

The Function of scraper

In SMT solder paste printing PCB board, one of the processes is to

use a scraper to squeeze solder paste, so as to transfer solder

paste from the steel screen to the PCB board. The scraper system is

the most complex motion mechanism on the printing press, including

the scraper fixing mechanism, the transmission control system of

the scraper, etc.

The function of the scraper system is to make the solder paste

expand into a uniform layer on the whole template area. The scraper

presses the template to make the template contact with PCB. The

scraper pushes the solder paste on the stencil forward while

filling the stencil opening; When the template is removed from the

PCB, leave a solder paste of appropriate thickness on the PCB

corresponding to the template figure

Specification

Model Item | ET5235 |

Screen Frames Min Size | 470*470mm |

Screen Frames Max Size | 737X737mm |

Screen Frames Thickness | 25~40mm |

PCB Min Size | 50X50mm |

PCB Max Size | 520X350mm |

PCB Thickness | 0.6~6mm |

PCB Warpage | <1% |

Transport Height | 900±20mm |

Transport Speed | Max 1200mm/S Programmable |

Board Location PCB Support System | Magnetic Pin/Up-down table adjusted/supportblock

by hand |

Clamping System Clamping System | side clamping,vacuum nozzle |

Print head | Two independent motorised printheads |

Squeegee Speed | 6~300mm/sec |

Squeegee Pressure | 0~10Kg/cm2 |

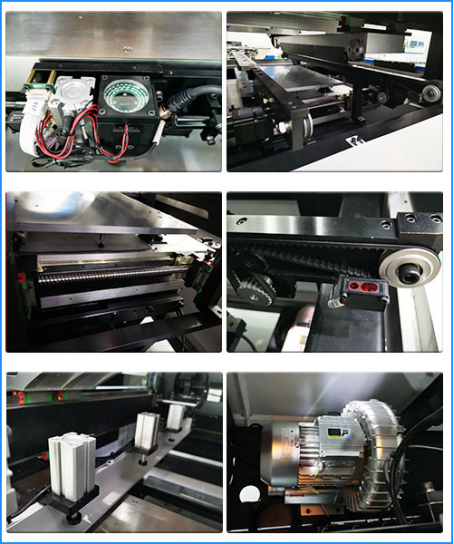

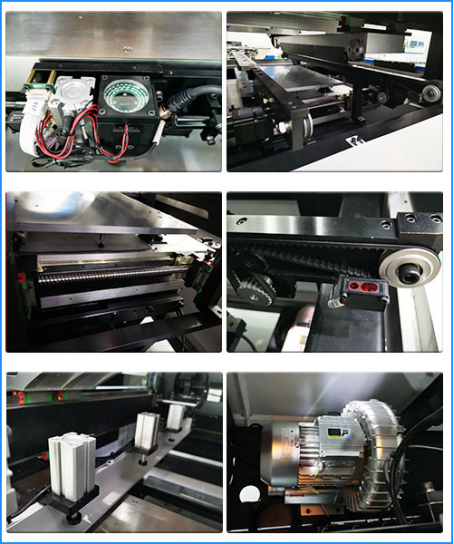

Machine's Feature

1. PCB transport and clamping system

The PCB loading direction can be selected and combined freely.

Unique crafted internal gear conveyor belt to prevent jamming.

2. Stencil positioning system

Arch bridge-shaped suspension hanging direct-connect scraper.

3. Scraper system

Cast aluminum scraper beam to ensure smoother running of scraper.

4. Operation interface

Easy-to-learn and easy-to-use friendly operation interface

5. Image and optical system

X,Y axis adopts high-precision grinding ball screw,driven by servo

motors at both side.

Service

Our service can be divided into three parts: pre-sales service,

in-sales service and after-sales service:

1)Pre-sales service can be called professional product

consultation. If you are particularly familiar with the patch

machine industry, we have special technical consultants to answer

the technical questions you want. If you want to move into this

industry, we also have special personnel who can provide some

information about the patch machine to make you more familiar with

the pick and place machine

2)Service in sales refers to that you have paid a deposit in

advance, and after the production of your products, we will

regularly share the progress of product production with you. Of

course, if you have other requirements during this period, you can

also say it, and then we will make your expectations for the

products.

3)After sales service refers to all the services we provide when

you receive the products. We have a special after-sales department

to serve you, such as guiding installation, training employees,

regular follow-up, sharing industry information and so on.

Clients

ETON as the leading manufacturer of global photo electronic high

speed pick and place machine, the products are exported more than

20 countries and regions, including India, Vietnam, Tunisia, Egypt,

Turkey, Russia, Thailand, etc.Take India as an example,We have many

big clients in India, Such as RK,SURYA,Fiem,Calcom,POLYCRB, etc. We

have sold over a hundred machines to India.

Contact me:

David

Whatsapp/Wechat/Tel: +86 13827425982

Skype: +86 15573907263

E-mail: david@eton-mounter.com

QQ:3061340868

Shenzhen Eton Automation Equipment Co.,Ltd.

The 2nd. Floor, Building C2, Hengfeng Industrial Area, Zhoushi Road

No.739, Hezhou community, Hangcheng Street,Baoan

district,Shenzhen,Guangdong,China.