SMT LED Mounting Machine: 68 Nozzles, 250000CPH Speed with

Automatic feeding

Technical Parameter

| Dimension | Length | 2700mm |

| Width | 2300mm |

| Height | 1550mm |

| Total weight | 1700kg |

| PCB | Length Width | Max:1200*330mm

Min:100*100mm |

| Thickness | 0.5-5mm |

| Clamping | Adjustable pressure pneumatic |

| Mounting mode | Group to take and group to mount. |

| Vision system | No.of camera | 5 PCS |

| Feature of camera | Vision alignment,MARK correction |

| Mounting precision | ±0.02mm |

| Mounting height | ≤5mm |

| Mounting speed | 250000CPH |

| Feeder station | 68 PCS |

| Nozzles | 68 PCS |

| components | LED3017,3020,3528,5050 and resistor,capacitor,bridge rectifiers. |

SMT

SMT is Surface Mount Technology (surface mount technology), which

is the most popular technology and process in electronic assembly

industry.

It is a pin-free or short-lead surface assembly components

(SMC/SMD, Chinese known as chip components) installed on the

Printed Circuit Board (PCB) surface or other substrate surface,

welded and assembled by reflow or dip welding and other methods of

circuit installation technology.

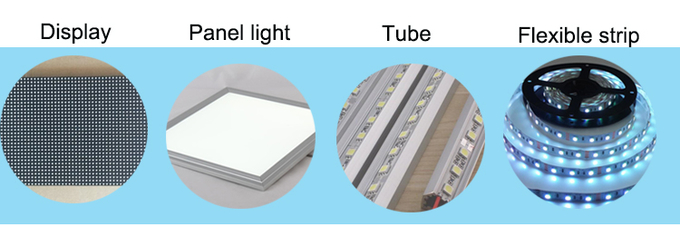

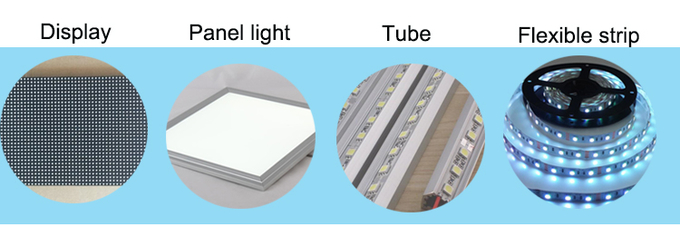

Application production&component

The mahcine mainly mounting linear produce,such as tubes, flexible

strips, panel lights, display screens,etc.

Honor client

ETON with more than 10 years experience in SMT LED manufacturer are

our partners in China.

Some details of the machine

Service

Maintenance Period: 1 year.(whole machine, any parts need to be

repaired or replaced will be free)

Upgrade the software will be free

Visit customer regularly and gather information.

Provide latest information about technology and equipment.

Related SMT machine:

We can provide you a whole SMT line solution and equipment, you can

look this picture, we have semi-auto/full-automatic stencil

printer, glue dispenser(this machine is mainly for making led

lens), conveyor, reflow oven, etc.

We can meet your any demands for equipment, and pursue quality

higher than price for machine manufacturing.

What is a pick and place machine used for?

Surface mount technology (SMT) is a widely adopted technique by

electronic manufacturers for the production of small and

medium-sized circuit boards. A pick and place machine, commonly

known as a surface mount technology machine or a SMT machine, is a

type of robot that enables placing electronic components onto the

printed circuit boards (PCBs) effortlessly and with high precision.

The primary function of a SMT machine is to automate the process of

placing numerous electronic components onto the PCB. The machine

follows an automatic procedure where a feeder feeds electronic

components, and a camera recognizes the components before securely

placing them on the designated destination on the PCB. This

operating technique not only enhances the precision of placing the

components but also streamlines the process of assembly at a faster

rate.

SMT machines have evolved over the years, and modern machines come

with several features that allow them to carry out additional

functions. The advanced machines have the capability of being able

to adjust the PCBs' orientation, handle a wider range of component

shapes and sizes, and fix the components at a faster rate than

their predecessors. Additionally, the machines have the ability to

work simultaneously on different PCBs, which has made them a

valuable asset in large-scale electronic manufacturing.

In conclusion, SMT machines have revolutionized the electronic

manufacturing industry, enabling manufacturers to produce small and

medium-sized circuit boards proficiently and at a faster rate. The

automated process of component placement is precise and efficient,

which has improved the quality of product output. This has made SMT

machines an invaluable asset for electronic manufacturers that

strive to stay competitive and maintain high-quality standards in

their industries.

Contact David

Whatsapp/Wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com